-

Injection Molding

-

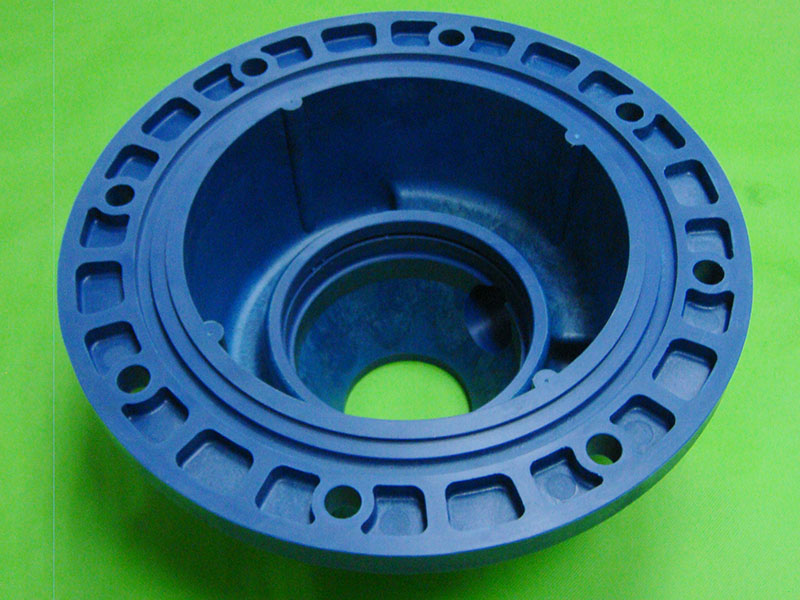

Pump Cover Production:

· Part name: Pump Cover

· Part name: Zytel 70G35HSL NC010

· Part weight: 3.7kg

· Part size: Dia325x170mm

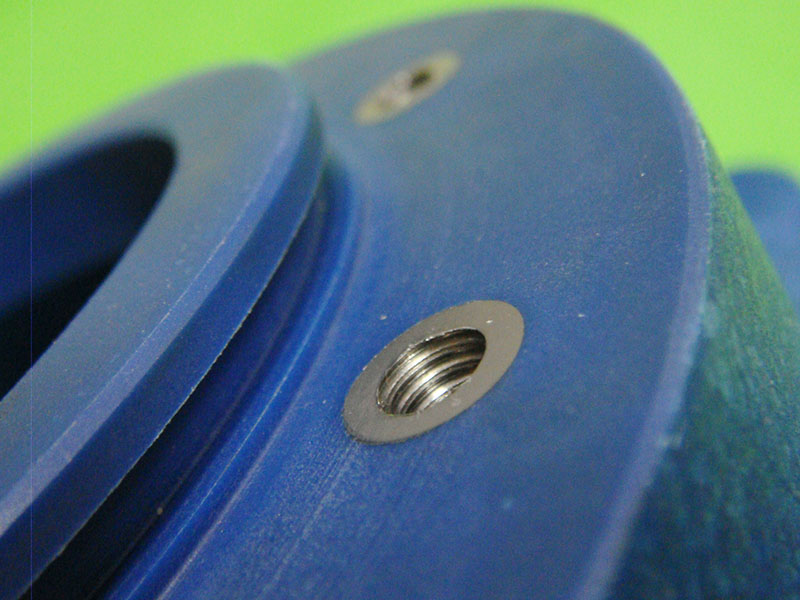

· Other: 8 pieces stainless steel 316 thread nut

· Molding press: 1000 Ton

· Mold size: 500x600x541mm

· Cycle time: 7mins

Main Challenges:

· Part weight is 3.7kg, the average thickness 12mm, the part cannot have air bubbles etc bugs

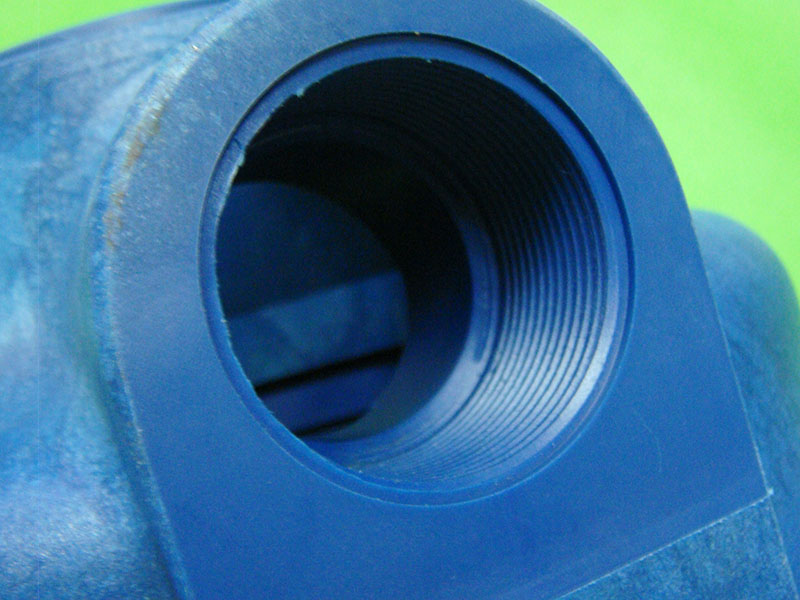

· Part need to pass safety test: under 15 bars of water pressure and keep at least 10 mins without leaking, destructive test higher than 25 bars

· Complicated machining details after molding and the machining need to be very accurate according to the technical drawings.

Our Solution:

· We used extremely of the press to inject the part with proper speed and pressure to make sure the part will have a weight of 3.7kg, this will

make sure molded parts have good quality and have no air bubbles within.

· Special test jigs were prepared for safety testing and destructive testing. This is a critical test for the molded parts quality judgment.

· Lot of special jigs were made for the molded parts CNC lathe machining, milling machining, drilling, and thread tapping.

· We also prepared the inspection jigs for quality control to make sure that the parts are good.

| EPLASTECH CO.,LIMITED 408, 4 Floor, C Area, B Block, West Silicon Valley, 5010 Bao'An Blvd, Bao'An, ShenZhen, GuangDong,518128, China Tell: 0086-755-86652783 Email: sales@eplastech.com |

本站部分图文来源网络,如有侵权问题请通知我们处理!

网站建设维护