-

Injection Mold

-

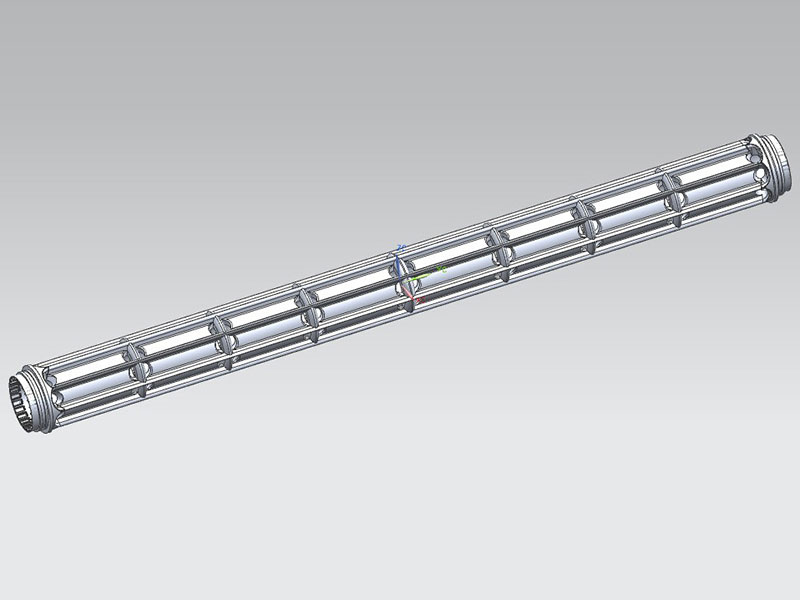

Project Features:· Part name: Filtration Cylinder

· Part material: PPS+50% glass fiber material.

· Part size: Dia56X654mm

· Mold Cavity: 1

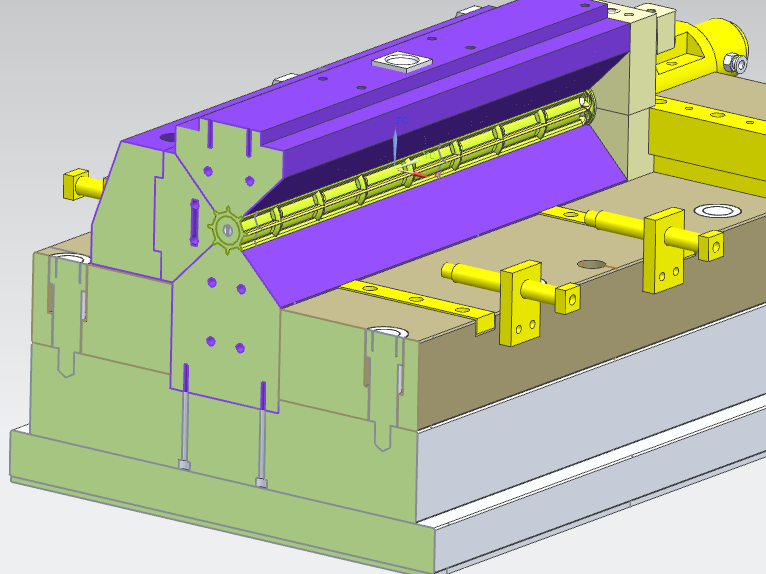

· Slider: 4 sliders, 2 were acted by slider guide pins and another 2 dragged by oil cylinder

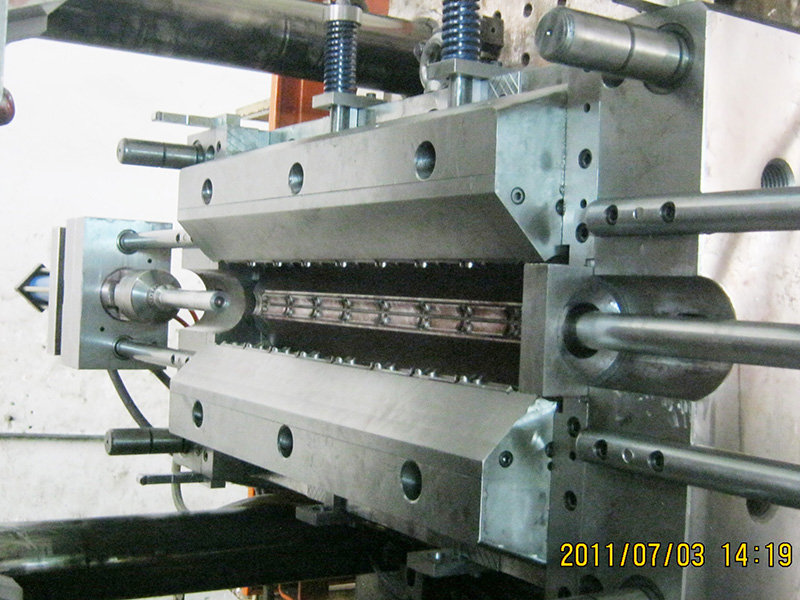

· Insert steel: H13 (HRC48-52)

· Mold size: 350X850X351mm (not including oil cylinder length)

· Injection gate: directly sprue

Main Challenges:

· The PPS+50%GF material requires high molding temperature and needs a very good heating system for the mold.

· The part inner thru hole is a diameter of 30mm and a length of 654mm, the slider molding for the inner hole needs to be worked

very well and keep the good part quality.

· Customer does not like the ejector mark on the external surface.

Our Solutions:

· Several layers of water lines were drilled to help the mold get enough heat during the molding, the mold was worked with

two mold heaters together during the molding.

· We made a special kiss-off structure for the two sliders kissing and enhanced the support in the two sliders' ends.

· The mold was designed without ejector pins or ejector plates. The part was released by the core moving back, a similar principle as

plate eject but in a different way. This makes the part molded without any ejector marks that satisfy customer requirements.

| EPLASTECH CO.,LIMITED 408, 4 Floor, C Area, B Block, West Silicon Valley, 5010 Bao'An Blvd, Bao'An, ShenZhen, GuangDong,518128, China Tell: 0086-755-86652783 Email: sales@eplastech.com |

本站部分图文来源网络,如有侵权问题请通知我们处理!

网站建设维护